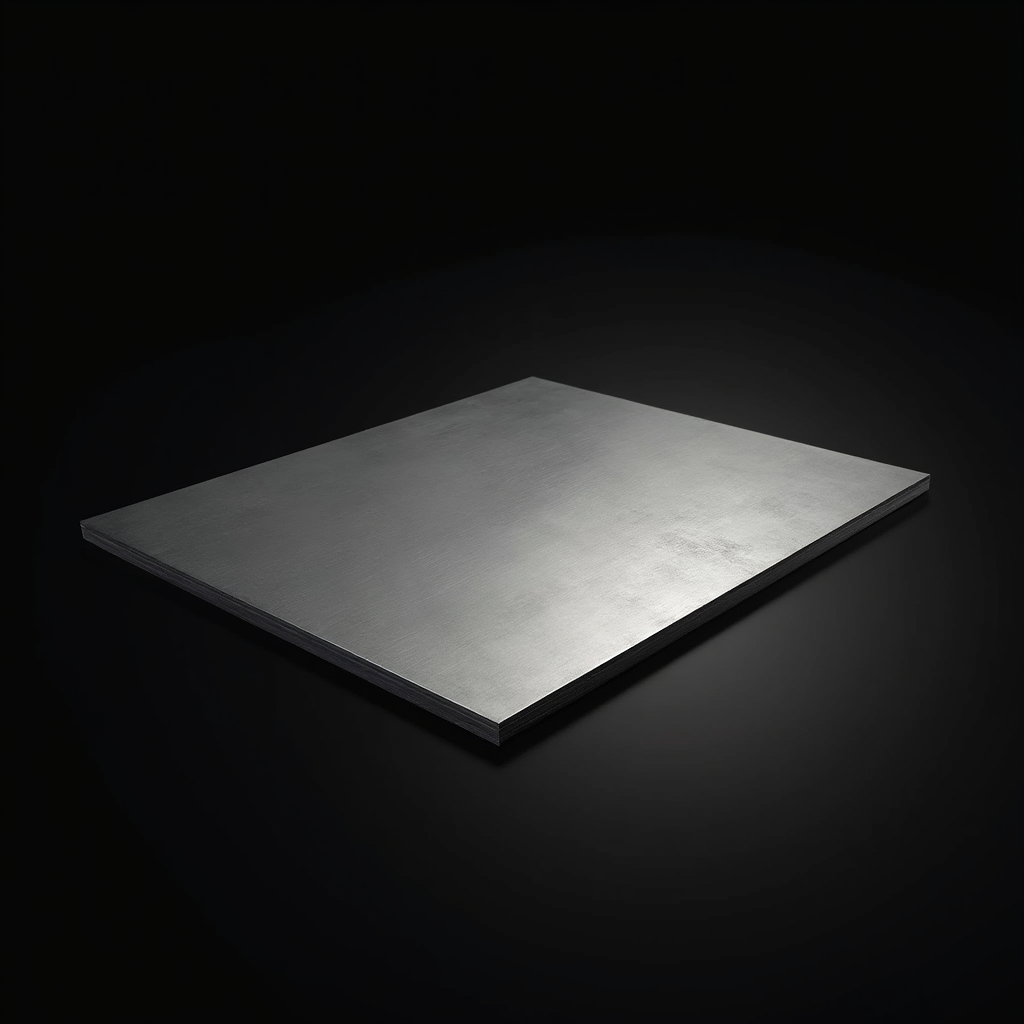

What is cold sheet?

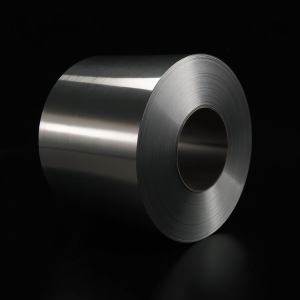

Cold rolled sheet is a type of steel sheet produced through the cold rolling process and is known as oiled sheet due to its appearance and impregnation with lubricant during the cold rolling stage. This product is considered one of the main products in the cold rolled sheet category and has higher resistance than hot rolled sheet.

Oiled sheet production is produced by a different rolling process than hot sheet due to the difference in working temperature. This product, which is produced from black sheet, is produced with skin pass methods to obtain a smoother, more uniform and higher quality surface. The use of oiled sheet is very common in various industries, including the automotive industry, the construction industry, the marine industry and the oil and gas industry due to its unique features. Given the quality and desirable performance of oiled sheet, our efforts to provide the best products and competitive prices continue to meet your needs in the best possible way.

Features and technical specifications of oiled sheet

Oiled sheet, with its combination of physical and mechanical properties, is considered a popular material in various industries for use in various projects.

- The sheet material is a steel sheet that is produced through cold rolling. This type of material has special cold rolling process, mechanical properties and ductility.

It gives a desirable look to the oiled sheet. - Standards Oiled sheet is produced according to internationally recognized standards such as ASTM A1008, BS EN 10130 and JIS G3141. These standards are

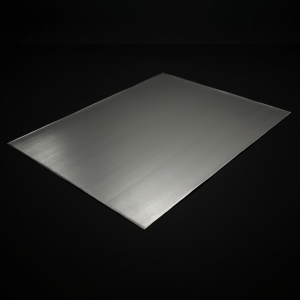

Quality assurance and compliance with international standards help. - Physical Properties Oiled sheet has specific physical properties that include thickness, width, and length. Typical sizes of oiled sheet include:

There are different thicknesses such as 3 to 30 millimeters and different dimensions such as 100 to 125 centimeters. - Mechanical properties Oiled sheet has important mechanical properties. These properties include tensile strength and flexural strength, which are

The basic components are used in evaluating the performance and various applications of oiled sheet. These characteristics may be based on

The standards and type of material produced by the manufacturer may be different.

Cold rolled sheet applications

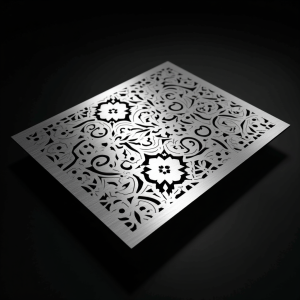

Cold rolled steel sheet applications include more sensitive and extensive applications due to their excellent surface and mechanical properties, as well as high dimensional accuracy. Among the most important applications of cold rolled steel sheet are the following:

- Aerospace parts and components

- Manufacturing of mechanical components and machinery

- Manufacturing of household appliances

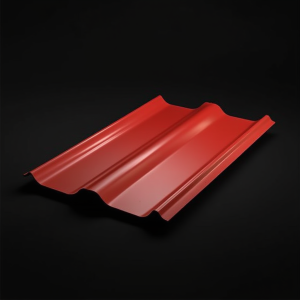

- Manufacturing of various types of oiled, galvanized and colored sheets

- Manufacturing sections such as various types of pipes, angles, gutters and steel profiles