What is colored galvanized sheet?

Colored galvanized sheets are a type of metal sheets that are pre-painted and covered with an electrostatic paint coating. This type of sheet has a wide variety of colors including red, blue, orange, white, green, silver, purple, pink, etc. and can be produced in thicknesses ranging from 18 microns to 1 mm.

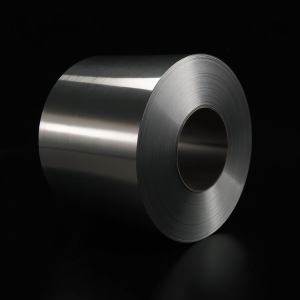

Colored sheets are produced by adding a hot-dip galvanized sheet to the galvanized sheet and have high resistance to corrosion and also have good formability. Colored sheets are initially produced in rolls (rings or coils), and the width of the rolls of colored galvanized sheet is 100 or 125 cm as standard, which are called short and long widths in the market, respectively.

In Iran, several factories produce and supply colored sheets, and each factory’s product is known by its own name in the market, including: Mobarakeh Isfahan colored sheets, Haft Almas colored sheets. Of course, Chinese colored sheets are also sold in the Iranian market.

Colored sheet production process

Galvanized sheets are degreased through a series of processes, and impurities are removed from their surface, and the surface of the sheets must be brushed with a series of rollers. After the brushing stage, their surface will become smooth and uniform, and the painting stage begins. After the painting stage, the washing, aeration, and drying stages are performed.

The painting process is also used for the base color with a type of primer base color on the bottom surface and on the sheet, after which the sheet is placed in a baking oven.

After this stage, the final paint can be made of polyester, epoxy, polyvinyl chloride, or polyurethane, and the paints must be baked again. At this stage, the final product with high resistance is prepared.

Types of colored sheets

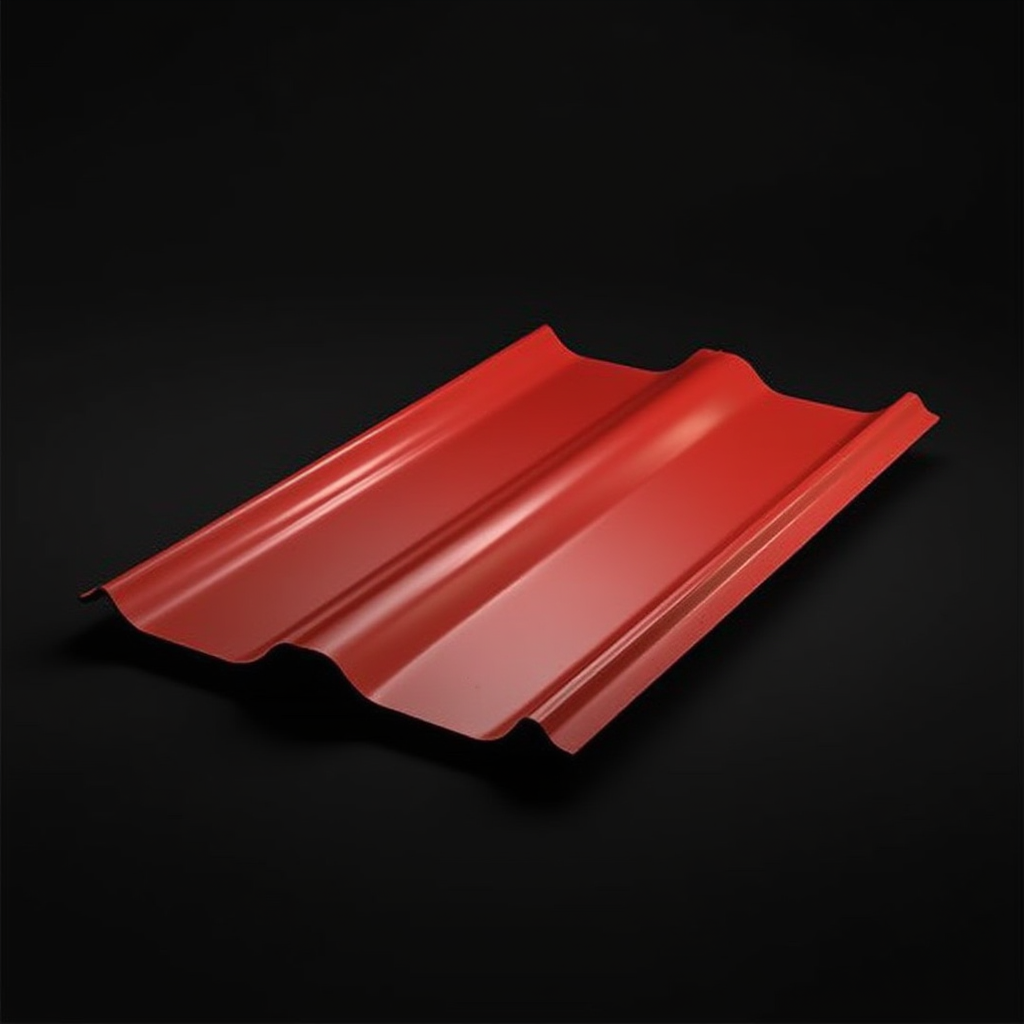

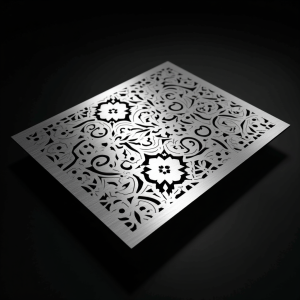

Colored sheets come in various types, including shutter, shadowline, pottery design, and Genoa, and the forming that can be created in this type of sheet can be trapezoidal, sinusoidal, etc. Of course, the cost of services, including forming, is charged separately or added to the base price of the colored sheet. The thickness of the paint on colored sheets can be from 20 to 25 microns, and the back of these sheets is between 7 and 15 microns.

Application of various colored sheets

Despite the beauty of these sheets, their only use is in roof and building facades and decorative items. Colored sheets are also used in various structural applications due to a combination of properties such as corrosion resistance due to the galvanized layer and color coating, high strength, light weight and affordable price. To learn about the process of coating colored sheets, refer to this link.

The most important uses of colored paper are:

- House roofs include gable roofs, shed roofs, halls, etc.

- Manufacturing of various containers

- Use in facades and decorations

- Construction of shed body, warehouse body, etc.

- Manufacturing of all kinds of cabinets and home appliances and…