What is tinplate?

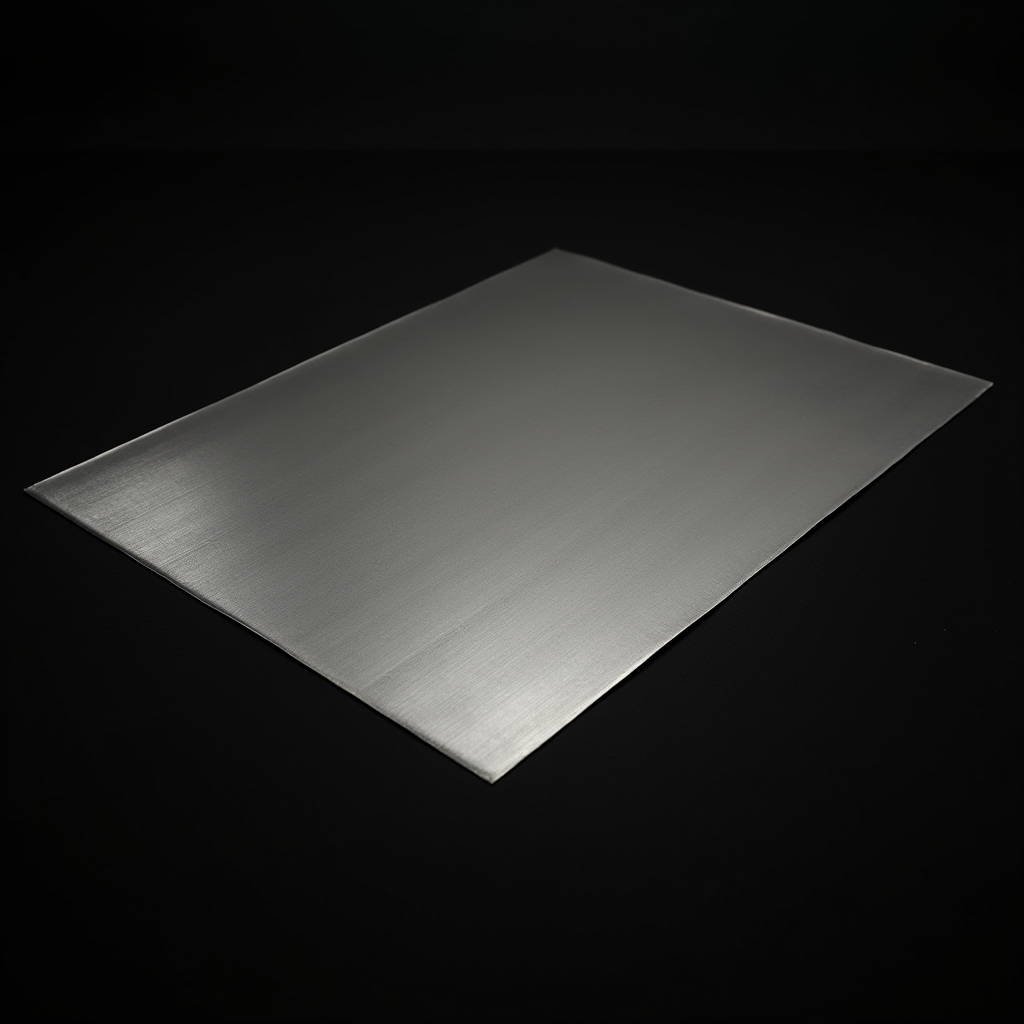

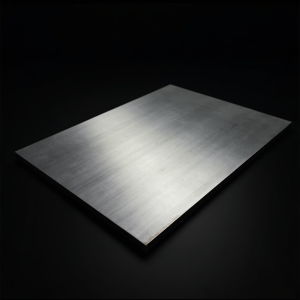

Tinplate is a steel sheet that is coated on both sides with a layer of the element tin by electrolytic deposition. This type of sheet has a beautiful appearance, high corrosion resistance, and high solderability. Tinplate is classified as a cold sheet and is produced and supplied in a wide range of thicknesses, surface finishes, and qualities. Electrolytic tinplate is a product that is obtained by electrolytically depositing tin on cold-rolled steel sheet in a continuous electrolytic tinning line to produce tin-plated coils or sheets.

The surface appearance of tinplate is determined by the following:

- Black sheet surface (which enters the cold rolling stage and then tin plating)

- Weight of coating applied to the sheet

- Surface melting or non-surface melting of the tin layer

Considering the above three parameters, tin-plated sheet can ultimately be produced and supplied with 5 types of appearance or, so to speak, 5 different finishes as follows:

- Shiny tinplate

- Fine stone coated tinplate

- Stone coated tin sheet

- Silver plated tinplate

- Matte tinplate sheet

What is tinplate?

Tinplate is a steel sheet that is coated on both sides with layers of the element tin by electrolytic deposition. This type of sheet has a beautiful appearance, high corrosion resistance, and high solderability. Tinplate is a cold-rolled sheet and is produced and supplied in a wide range of thicknesses, surface finishes, and qualities. Electrolytic tinplate is a product that is obtained by electrolytically depositing tin on cold-rolled steel sheet in a continuous electrolytic tinning line to produce tin-plated coils or sheets. The following figure shows the layers of a tin-plated steel:

The surface appearance of tinplate is determined by the following:

- Black sheet surface (which enters the cold rolling stage and then tin plating)

- Weight of coating applied to the sheet

- Surface melting or non-surface melting of the tin layer

Considering the above three parameters, tin-plated sheet can ultimately be produced and supplied with 5 types of appearance or, so to speak, 5 different finishes as follows:

- Shiny tinplate

- Fine stone coated tinplate

- Stone coated tin sheet

- Silver plated tinplate

- Matte tinplate sheet

Tinplate coating

Tinplate coating refers to the total coating on both sides of the sheet in grams per square meter (gr/m 2 ). The specified coating mass must be compatible with the thickness of the base metal, the formability requirements, and the expected service life for the intended use. Tin plating, due to its unique characteristics, gives various properties to metal sheets to the extent that many of the disadvantages and problems of metal sheets are eliminated with this coating. For example, using tin plating delays erosion and thus provides a rust-proof state. It is interesting to know that tin metal cannot be used to make a sheet. For this reason, a sheet made of steel is tin plated so that the properties of tin metal can be utilized in the sheet.

How is the mass of tin coating in tin-plated sheet determined?

As we said, the mass of tin coating on both sides of the sheet is expressed in grams per square meter (gr/m 2 ). The mass of the coating must comply with the requirements of the Iranian National Standard. The minimum allowable amount of coating specified in the standard must be gr/m 2 on each side of the sheet, but no upper limit is specified. In general, the most commonly used values for the weight of tin coating include 11.2, 8.4, 5.6, 4, 2.8, 2, 1.4, and 1. In the table below, you can see the mass of the coating of tin-plated sheet (total of both sides) according to the Iranian National Standard. To use the table below, you must first familiarize yourself with the method of marking the coating of tin-plated sheet in the national standard, which we will introduce below. The marking indicates the coating, coating mass, coating condition, and quality, and is as follows:

- SN: means tin plated

- BR: Bright, surface-melted

- MA: Matte, non-glare, no surface melting

- The numbers 01, 02, 03 and 04: indicate the qualities of normal, tensile, deep-drawn and deep-drawn aluminum-calibrated. For example, the designation SN056BR03 means as follows:

SN: Tin plated

056: with a nominal coverage of 5.6 grams per square meter (see Table 2)

BR: Has a shiny surface (surface-melted tin)

03: Deep pull quality

Types of tinplate

Sheet metal is usually classified according to the type of alloy used to make it and other criteria. The most important and well-known type of classification of tinplate is related to its degree of softness and hardness . Single cold-rolled tinplate is classified according to the temper degree and hardness values obtained, and double cold-rolled sheets are classified according to the stress values.

The classification of tinplate in terms of hardness includes the following:

- Tinplate with temper 2: with soft hardness

- Tinplate with temper 3: with normal hardness

- Tinplate with temper 4: with a hard hardness grade

Tinplate dimensions

Electrolytic tinplate is usually produced in specific thicknesses and widths as follows.

- Tinplate thickness: from 0.50 mm to 0.85 mm

- Tinplate width: 600 to 1050 mm in roll and sheet form.

Introduction to tinplate production standards

This category of products is produced in compliance with national and international standards. Among the standards developed for the production of tinplate are the following:

- National Standard of Iran INSO 15997

- National Standard of Iran INSO 21099

- International Standard ASTM 623

- International Standard ASTM 657

- International standard JIS G 3303

- International standard EN 10203/91

- Standard International ISO 5950:2012

- International standard ISO 11949-2016

Features and characteristics of tinplate

Considering the base metal used in the manufacture of the sheet and its coating, it can be admitted that this sheet has a very high resistance. Other characteristics of tin-plated sheets include the following:

- No premature wear

- Rustproof capability

- Flexibility

- High resistance

- Uniform thickness of sheet surface

- Beautiful appearance

- Wide application

- Corrosion resistance

- Variation of the coating mass

- Soldering capability

In addition to the technical and appearance features mentioned above, tinplate has 5 other outstanding characteristics, including the following:

- High solderability: Tin-plated sheet has excellent solderability, and for this reason, this method is usually used to connect sheets, but if welding is required, if the appropriate welding conditions are chosen, this sheet is also suitable for welding.

- Wide mechanical range: Compared to other steel sheets, this sheet has a wide production range based on mechanical specifications. For example, tin-plated sheet is produced and available in 5 different finishes and 3 different types of textures.

- Reducing environmental pollution: If tin-plated sheet metal is placed in nature, it returns to the natural cycle through reactions such as oxidation. Therefore, according to experts, this sheet metal is less polluting than other steel sheets and is a good choice for the health of the Earth’s ecosystem.

- Easy recycling: This feature applies to almost all steel sheets. Iron, due to its good magnetic absorption, is easily separated from the bulk waste and returned to the recycling cycle. Usually up to 80% of the waste generated from metal sections is recycled using this method.

- Oil coating: Electrolytic tinplate always has a layer of oil on both surfaces of the sheet. The presence of oil minimizes surface abrasion. It is important to note that this oil is easily removed with degreasers and is not suitable for lubrication in drawing or forming.

Mechanical properties of tinplate

The mechanical properties of tin-plated sheet should be as per the table below. Long-term storage of tin-plated sheet can cause changes in the mechanical properties of the sheet (increased hardness and elongation). As a result, the sheet’s ductility decreases. Therefore, if long-term storage of tin-plated sheet is required, it is better to purchase quality 04 sheet to minimize this effect.